Unlocking Efficiency and Quality: The World of Lube Oil Blending Plants

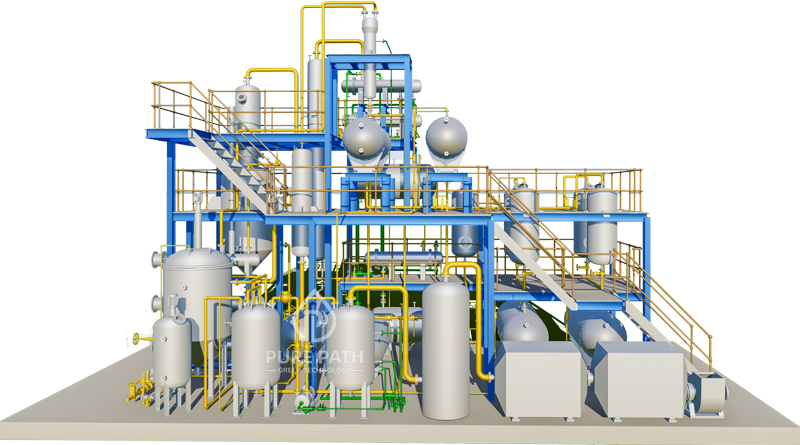

In the realm of industrial lubricants, lube oil blending plants play a pivotal role in ensuring the smooth operation of machinery across diverse sectors. These facilities are the heart of the lubricant production process, where various base oils and additives are carefully mixed to create the precise lubricants needed to keep engines, machinery, and equipment running smoothly. In this article, we delve into the fascinating world of lube oil blending plants, exploring their significance, processes, and the critical role they play in industries worldwide.

The Significance of Lube Oil Blending Plants

Lubricants are the unsung heroes of machinery. They reduce friction, dissipate heat, and protect vital components from wear and tear, extending the lifespan of engines and equipment. The importance of lubrication cannot be overstated, making lube oil blending plants essential to countless industries, including automotive, manufacturing, aviation, marine, and more.

These blending plants lube oil blending responsible for producing a wide range of lubricants, each tailored to meet specific requirements. From engine oils to industrial lubricants, hydraulic fluids to gear oils, lube oil blending plants ensure that the right lubricant is available for every application, guaranteeing optimal performance, efficiency, and durability.

The Lube Oil Blending Process

Lube oil blending is a meticulous process that demands precision, quality control, and adherence to strict industry standards. The process can be broken down into several key stages:

- Base Oil Selection

At the core of lube oil blending is the selection of base oils. These oils are chosen based on their properties, such as viscosity, oxidation stability, and temperature resistance. Blending plants often use a combination of base oils to achieve the desired lubricant characteristics.

- Additive Incorporation

Additives are the secret ingredients that enhance lubricants’ performance. Antioxidants, detergents, dispersants, anti-wear agents, and viscosity modifiers are just a few examples of additives used in lubricant formulations. The precise quantity and combination of additives are carefully calculated to meet specific performance standards.

- Blending and Homogenization

The selected base oils and additives are mixed together in blending tanks. The blending process ensures that the components are thoroughly combined and homogenized to create a consistent lubricant mixture.

- Quality Control

Quality control is a critical aspect of lube oil blending. Samples are taken at various stages of the blending process and subjected to rigorous testing to ensure that the final product meets the required specifications. These tests include viscosity measurement, oxidation stability analysis, and performance testing in simulated operating conditions.

- Packaging

Once the lubricant meets all quality standards, it is prepared for packaging. Lubricants are packaged in various containers, including bottles, drums, and bulk tanks, depending on the intended use and market demand.

Environmental Considerations

In recent years, lube oil blending plants have been increasingly focused on sustainability and environmental responsibility. Many plants have adopted eco-friendly practices, such as reusing and recycling materials, reducing waste generation, and optimizing energy efficiency. Additionally, the development of environmentally friendly lubricants with biodegradable base oils has gained traction, aligning with global efforts to reduce the environmental impact of industrial processes.

The Future of Lube Oil Blending Plants

As industries evolve and embrace new technologies, lube oil blending plants are also adapting to meet changing demands. Automation and digitalization are becoming integral to plant operations, enabling real-time monitoring, precise control, and enhanced quality assurance. Furthermore, the development of advanced lubricants designed for the high-performance demands of modern machinery is pushing blending plant capabilities to new heights.

In conclusion, lube oil blending plants are the unsung heroes behind the scenes, ensuring that the wheels of industry keep turning smoothly. Their role in producing high-quality lubricants that enhance the performance and longevity of machinery cannot be overstated. As these facilities continue to innovate and prioritize sustainability, they are set to remain a cornerstone of industrial operations, supporting global progress for years to come.